Why proper electrical grounding and bonding are critical for safety and long-term durability.

Importance of Grounding and Bonding of a Geodesic Dome Tent.

A geodesic dome tent is a versatile, customizable, cost-efficient and semi-portable structure suitable for various private and commercial projects. These domes can be placed on different surfaces and are available in various sizes. They make excellent outdoor camping solutions and glamping setups with their spacious, open-concept interiors. Depending on your setup, geodesic domes can also be connected to electricity and water supplies, providing comfortable living spaces.

However, using electricity introduces the risk of the dome structure becoming electrically energized, which is a serious safety concern. This issue can lead to severe accidents if not properly addressed. The solution lies in grounding and bonding the steel frame of the geo dome. This article explains the importance of grounding, discusses potential risks to the dome's structure, and outlines the basic principles of grounding and bonding techniques.

Geodesic dome structure and potential risks.

Geodesic or glamping domes are constructed using galvanized steel pipes and PVC-coated polyester membranes, creating lightweight, self-supporting structures capable of withstanding various weather conditions. These domes are typically installed directly on the ground or on platforms made of wood or concrete. It's recommended to use a platform that matches the dome's diameter to provide solid foundation support, stabilize flooring, and ensure a watertight seal around the base.

However, when using power plugs and electrical equipment, there's a risk that the galvanized steel frames of glamping geodesic dome tents could come into contact with electrical wires, potentially causing the structure to become "live." This poses safety concerns and underscores the importance of implementing proper grounding and bonding methods to effectively mitigate these risks.

The significance of Grounding and Bonding.

Grounding and bonding are crucial for ensuring safety, protecting equipment, and defending against lightning strikes. When an appliance's metal cover becomes electrically charged, grounding prevents electric shocks. Bonding, on the other hand, shields against unexpected shocks and is vital when multiple conductive devices are located or installed close together.

Bonding alone isn't enough—it works alongside grounding to equalize electrical potential between metal bodies. The purpose of bonding is to remove the electrical potential difference between two conductive metal bodies, and it is recommended when installing electrical equipment or appliances. Without a conductive path to the ground, static charges can't be dissipated. Grounding directs excess current safely into the earth, preventing harm by creating a low-resistance path. This process ensures that people remain safe from electrical shocks.

Grounding is the flow of excess current from metal bodies or electrical lines to the ground wire without causing harm to human body because the current flows from a high potential point to a low potential point and, in this case, the ground wire serves as a low potential medium. The human body does not attract excessive current while there is grounding because it has equal positive and negative charge, hence declared as a neutral object. Otherwise, it gets shocked due to a fault current. If a conductive surface somehow gets energized, then the proper grounding conducts the electricity into the ground of the earth. The grounding of a geodesic dome frame makes it more shockproof and safe for living. A dome tent without grounding or with improper grounding may have a risk of fire and electrical shocks, which can result in injury or death.

For geodesic dome tent structures proper grounding enhances safety significantly, making them more resilient to shocks and safer for inhabitants. Conversely, domes lacking or improperly grounded pose risks of fire and electrical accidents, potentially leading to severe injuries or fatalities.

Factors that can result in the dome tent frame becoming electrically charged.

Attaching power outlets and cables directly to the steel frame of the dome, placing the dome structure beneath overhead power lines, and even lightning can result in the dome tent structure becoming electrically charged.

Important Safety Tips:

NEVER INSTALL ANY ELECTRICAL PLUGS, CABLES, APPLIANCES OR DEVICES DIRECTLY ON THE DOME STEEL FRAME STRUCTURE.

The best approach is to build interior wooden frame walls and install power cables and plugs within them, just like in a conventional house (see Figure-1).

Fig. 1

Potential Electrical Hazards:

Overhead Power Lines: These can generate a high magnetic field due to the flow of current, which may energize the dome's structure.

Lightning: While typically affecting taller structures (30 meters or approx. 100 ft), even residential structures around 15 meters (50 ft) should have a lightning arrester system. This system includes a lightning rod connected to a grounding cable (see Figure-2). Large geodesic domes should also have a lightning rod installed at the top center of the frame for protection.

Fig.2

The use of high-reflective bubble foil layer as insulation.

To insulate the walls of a dome tent, we use a durable reflective bubble foil layer stitched with a layer of canvas (see Figure-3). This insulation reflects infrared radiation (heat), helping to keep the inside of the dome warmer in winter and cooler in summer, thereby reducing the load on heating and cooling systems. It is quite lightweight, durable, and has a long service life.

Fig. 3

The insulation is made by bonding polyethylene air bubbles between two layers of highly reflective metallized aluminum polyester film.

The term "metallized" can be confusing. It refers to the process of coating a thin layer of metal on an object. In this case, a thin layer of aluminum, about 0.5 micrometers thick, is deposited onto the surface of a polyester substrate, creating a bright, shiny film. This film is non-conductive, similar to those used as dielectric mediums in capacitors, NASA spacesuits, and fire-fighter proximity suits to reflect heat radiation.

For further clarity, here is a continuity test performed on the reflective insulation layer: TEST VIDEO.

How to ground and bond a dome tent structure.

Learning how to properly ground and bond a geodesic dome tent involves several key steps:

1. Ensure Conductors are Suitable: Conductors used for grounding or bonding the steel dome frame must be checked for electrical continuity and capacity to carry current. Visually inspect all connections along the grounding path. Use a digital multimeter to verify continuity by connecting its test leads across the conductor or component.

2. Electrode Coatings: Check grounding electrodes to ensure they are free from coatings such as epoxies, ceramic coatings, or enamel paints.

3. Ground Rod Installation: Install the ground rod below the permanent frost level. The rod should be at least 8 feet in length and driven into the earth to ensure proper contact. Before installation, confirm with local authorities that there are no underground utilities (electrical, gas, water, telecommunications) in the vicinity.

4. Compliance with NEC Standards: Refer to the National Electrical Code (NEC) Section 250-56, which requires a single ground rod or ground plate to achieve an earth resistance of 25 ohms or less.

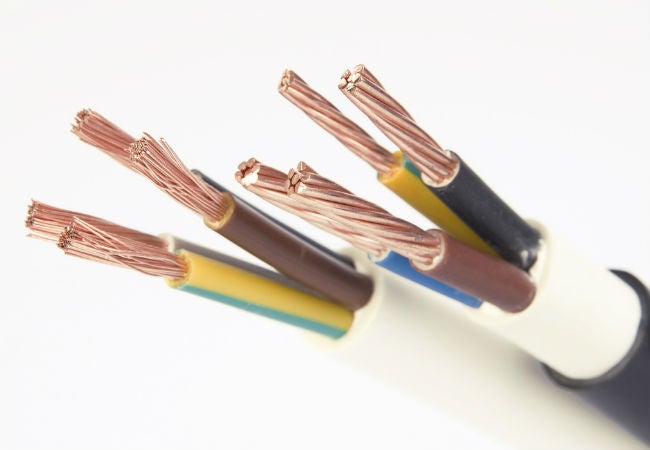

5. Equipment Grounding Conductors: Use equipment grounding conductors that run with or enclose circuit conductors to ground all electrical appliances (see Figure 4). LEARN ABOUT WIRING COLOR CODES.

Fig 4.

6. Bonding Electrical Devices: Use at least a #6 AWG copper conductor to bond electrical equipment and metal structures.

7. Grounding the Steel Pipe Dome Frame: Ground the galvanized steel pipe dome frame by connecting a #6 or #8 AWG copper conductor to the bottom hub of the structure (refer to Figure 5). Install an 8-foot copper-coated steel rod vertically in the ground. In rocky soil, drive the rod at a 45-degree angle from vertical; in other soils, bury it horizontally at least 2.5 feet deep (refer to Figure 6).

Fig 5.

Fig 6.

8.

8.

8. Ground Resistance Testing: Verify that the grounding system has a total resistance of less than 1 mega-ohm. Use a "Clamp-on Ground Resistance Tester" (refer to Figure 7) to measure resistance, considering soil moisture impacts. It is a mandatory to inspect the grounding system to ensure continuity and correct resistance.

Fig. 7

Important Note: The Glamping Dome Store recommends engaging a licensed electrician to inspect and approve all electrical work inside or near your geodesic dome tent.

Ensuring a safe and enjoyable experience in your geodesic dome tent goes beyond just comfort and aesthetics; it extends to addressing crucial safety measures, especially when dealing with electrical systems. Grounding and bonding are essential to prevent serious hazards and protect both the structure and its inhabitants. By following the guidelines and recommendations outlined in this article, you can create a secure environment that enhances the overall functionality and safety of your dome tent.

Investing in a geodesic dome is not just about acquiring a unique and versatile space; it's about embracing a lifestyle that blends innovation, sustainability, and safety. As you embark on this journey, remember that proper installation, including grounding and bonding, is vital for a successful and secure setup. With the right precautions, your geodesic dome can become a haven of comfort, adventure, and peace of mind.

Additional sources:

- Shetty, P., & Alkonda, V. (2022). Glamping–understanding a new tourism trend in Maharashtra.

- Pierce, A. (2010). The use of grounding and bonding to reduce the risks of static electric potentials and help in preventing them.

- Vijayaraghavan, G., Brown, M., & Barnes, M. (2004). Practical grounding, bonding, shielding and surge protection. Elsevier.

- Vlad, A., & Balducci, A. (2017). Porous materials get energized. Nature materials, 16(2), 161-162.

- Cain, J. B., & McKay, N. (1991). Thermal radiative properties of metallized films. Journal of Thermal Insulation, 14(3), 221-240.

- Li, D., Tai, Q., Feng, Q., Li, Q., Xu, X., Li, H., ... & Xiong, C. (2014). Highly reflective and adhesive surface of aluminized polyvinyl chloride film by vacuum evaporation. Applied surface science, 311, 541-548.

- Durham, R. A., Szczecinski, S. J., & Durham, M. O. (2020). Factors impacting selection of grounding and bonding conductors. IEEE Transactions on Industry Applications, 56(5), 4652-4661.

- Durham, R. A., Szczecinski, S. J., & Durham, M. O. (2018, September). Grounding and Bonding Conductors: Solid, Stranded, Bare or Insulated?: Copyright Material IEEE, Paper No. PCIC-2018-03. In 2018 IEEE Petroleum and Chemical Industry Technical Conference (PCIC) (pp. 19-28). IEEE.

- Ufer, H. G. (1964). Investigation and testing of footing-type grounding electrodes for electrical installations. IEEE Transactions on Power Apparatus and Systems, 83(10), 1042-1048.